iNOBox

Web based tool for innovative processing technologies

Teaming up with key industry and market players, the main goal for the iNOBox research project was to integrate in the Norwegian food industry more efficient, profitable and sustainable processing, securing the supply of safe, high-quality and nutritious foods.

Start

01. Apr 2018

End

30. Sep 2022

Funded by

The Research Council of Norway

Cooperation

Nofima (NO), Veterinærinstituttet (NO), Østfoldforskning (NO), University of Liverpool (UK), Campden BRI (Chipping Campden) Limited (UK), Universidad de Zaragoza (ES), TNO (NL), BAMA Gruppen AS (NO), Den Stolte Hane AS (NO), Findus Norge AS (NO), Fjordkjøkken AS (NO), Fjordland AS (NO), HOFF AS (NO), MatBørsen AS (NO), Advanced Microwave Technologies Ltd (UK), Elea Gmbh (DE), Hiperbaric SA (ES/US), UV Technology Ltd (UK)

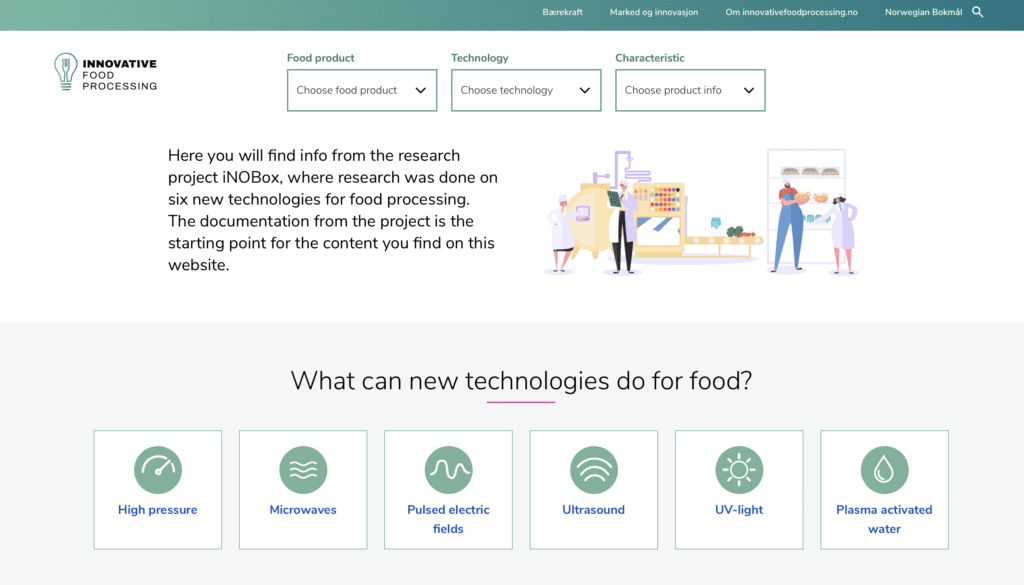

Web based tool

Knowledge and documentation about the effects of the six technologies available all in one place.

Check it out!

Objectives

The iNOBox reseach project aimed to develop a web-based innovation toolbox to help food industry make informed decisions on process innovation, overcome bottlenecks to market and ensure innovative products reach the consumers. The e-toolbox was built upon durable projects outputs and external data sources, enabling effective knowledge sharing of iNOBox outcomes.

With food security set high on the socio-political agenda, innovative food processing technologies can help to meet the demand of sustainable and affordable healthy diets for a growing and aging population.

Safer and healthier foods resulting from innovative processing will improve the public health system through reduced prevalence of food allergy, diet-related diseases, food recalls and associated health/social costs.

Economical, social and environmental impact

The Norwegian food industry is challenged by a stringent environmental policy, pressure on food self-sufficiency/security, domestic market competition, new consumption patterns & low R&D expenditure stifling innovation. iNOBox represents a joint multi-actor effort towards more efficient, profitable & sustainable processing, securing the supply of safe, high-quality & nutritious foods.

iNOBox proposed five market-driven business solutions with broad transferability that integrate innovative processing technologies (IPT) across relevant agri-food chains. iNOBox greatly advanced cross-disciplinary knowledge base on IPT and paved the way towards market & consumer uptake. The innovation e-toolbox supports IPT end-users/manufacturers on scientific, technical, regulatory and sustainability matters, and supports decision making in marketing strategies.

Through whole value-chain interventions, resource-efficient IPT will foster:

- Environmental, economic & social sustainability towards a circular bioeconomy: better self-sufficiency, cost optimisation; 1.5-5% energy saving in the whole sector; 0.1% GHG emission reduction in Norway, 438 MNOK/yr consumer savings (food waste) for each extra day’s shelf-life

- Fast-growing productivity, long-term profitability & competitiveness

- Better employability of a high-skilled workforce in decentralised areas.

- Safer & healthier IPT foods will lead to new market shares & social innovation (allergy, health promotion) and will improve the public health system through reduced prevalence of food allergy/diet-related diseases, food recalls & associated health/social costs, while contributing to food security for a growing/ageing population.

The iNOBox project fostered international responsible research and innovation, multi-actor and public engagement, science education, open knowledge sharing and gender/ethical integrity, towards better decision-making on sustainable process innovation and enhanced know-how/technology transfer.

Through cross-disciplinary research, iNOBox aimed at greatly advancing the current knowledge on the innovative technologies cold plasma, pulsed electric fields, ultrasounds, UV-light, high-pressure processing and microwaves.

Consumers will also benefit from reduced food waste through the extended shelf-life of innovative foods (438 MNOK/yr savings for each extra day of shelf-life). iNOBox outcomes also aimed at helping foster energy savings in the food sector (1.5-5%), reduced gas emissions (0.1% on national level) and high-skilled jobs in decentralised areas.

To ensure the successful implementation of innovative processes, food producers must be aware of their benefits (and how to communicate them to the consumers), their suitability for different products/applications, as well as scientific, technical and regulatory aspects.

Consortium

Led by Nofima, the iNOBox team included (inter)national research and industry partners and provided unique training opportunities to young scientists (2 PhDs and 2 Postdocs).

Some of what we have done

- Annual Consortium meetings and regular management committee meetings and consortium calls.

- SOPs for chemical analysis of PAW set up. Effect of water temperature & composition on PAW assessed. PAW Literature review and work on new technics. New spinach pathogen trials.

- In pack microbial reduction trials are carried out on pork and chicken. Pathogen trials using Salmonella and E.coli (chicken) and Salmonella, Listeria and Staphylococcus (pork) at a fixed UV-C dose.

- Liquid whole egg fortified with green tea extracts (2 types) subjected to high pressure (HP). The eggs have been characterized for functional, microbial, and structural properties. Study on HPP & MW (incl. modified atmosphere packaging & soluble gas pre-stabilisation) for preservation of cooked chicken.

- Experiments with tubular MVH, HPP PEF and traditional heating for pasteurization of milk performed. Homogenisation was performed with ultrasound.

- US-assisted freezing on meat quality. Experiments on the potential of PEF (ohmic heating) for blanching vegetables before freezing/drying are conducted. PEF chamber & US prototype built up. Study on PEF & US for meat drying/freezing/thawing.

- Process and product characterization of ‘smart yoghurt’, produced with milk treated with combination of CO2, HPP and US.

- Chicken samples analyzed by MS metabolomics for studying metabolite profiles caused by different processing technologies and storage periods.

- Raw liquid whole eggs produced with US and PEF have been analyzed with sera of patients with egg allergy.

- In vitro digestion studies on processed chicken fillets; no effect of HPP, MW, US and PEF treatment on protein digestibility, but PEF with heat caused increased peroxidation during digestion. Similar experiments with eggs will be followed up by gut fermentation studies.

- A Cradle to grave Life Cycle Analysis for chicken production and slaughter. Nutrient density indicator and method transferability to allergens.

- A Marketing Communication Decision Support Tool has been developed, based on consumer studies and feedback provided by iNOBox partners.

- Data and information from EU Novel food database and patent database has been analyzed.

- Web development including user testing, design architecture and content production. Animation films explaining the effects of the technologies on various foods. News updated on website inobox.no, in several media and partners’ channels. Newsletters provided to subscribers every 6 months.

- Research stay of PhD student from the University of Zaragoza to Nofima completed in the autumn of 2021.

Animation films from the project

Dissemination

Project partners have presented the project and its progress to cross-diciplinary target groups, including end users. In Cristin (Current Research Information System in Norway) you can find all publications registered on the project.

Publications registered in Cristin

Publications

Research areas

Food processing technologies

Shelf life and food safety

Marketing strategy

Diet and health

Product development

Research facilities

Research facilities at Måltidets hus

Similar projects