Worth knowing about microwaves in food production

Many people use microwaves to heat food quickly in their home kitchen. Similarly, the food industry uses microwaves for rapid processing of foods before they reach the shops. Rapid heating preserves the quality and nutritional content of the food.

Why process raw materials and food products by microwaves?

Food and beverages that will be sold in shops often need to be processed to maintain food safety and shelf life requirements.

The advantages of using microwaves for processing in food production include:

- Faster heat treatment and drying

- Better preservation of nutritional content due to short heat treatment time

- Increases shelf life, thereby reducing food waste

- Uses less electricity than some other heat treatment methods

- Saves water during pasteurisation

How does microwave processing work?

It is the water content in the food that allows microwaves to heat the food so quickly and gently. Microwave ovens work by sending microwaves into the food that cause water molecules to vibrate, and these molecules are thus quickly heated in the product, helping to transfer the heat further into and around the food.

Unlike boiling and frying, where heat is transferred to the food from the outside and inwards towards the core and where the surface will always be exposed to the highest heat load, microwaves can heat the product quickly from the ‘inside’, which is gentle on the food.

How microwaves affect shelf life and food safety

It is possible to extend the shelf life of packaged foods by heating and cooling them. With intense heat treatment and suitable packaging, sterile food with years of shelf life at room temperature can be produced, but even milder heat treatment combined with refrigerated storage can increase product shelf life by several weeks.

There is much readily available knowledge about the effects of heat processing of food that also applies to microwaves, but microwaves stand out in three ways:

- It is not necessary to use much water to cook something with microwaves, since the food cooks from the inside out. Boiling in a pot with water leads to the loss of water-soluble vitamins to the cooking water. Therefore, nutrients are better preserved when using microwaves.

- The very rapid heating makes it possible to heat treat for a short time at high temperature. For pasteurisation or sterilisation of vegetables, this is particularly beneficial because several important nutrients are best preserved by a short heat treatment.

- However: The temperature distribution in the food can be difficult to predict in a microwave process. Conversion of microwave energy to heat depends on the product’s geometry, temperature and content of water and fat, among other things. Overheating in edges and corners can also lead to the product being burnt.

In some places in the product, the temperature may become lower than planned, allowing bacteria that should be inactivated during pasteurisation to survive. This can be compensated for by safety margins, for example by heat treating longer, but then some of the advantages of microwaves are lost.

Much of the research in this area has therefore focused on being able to predict the temperatures that develop with better accuracy.

What does the food industry use microwaves for?

The most common applications for microwaves in the food industry today are for food preservation (pasteurisation, sterilisation and drying), tempering and thawing, and in combination with other technologies for various purposes, such as vacuum drying, pre-treatment before hydrolysis, etc.

Pasteurisation and sterilisation with microwaves

Many foods and beverages are pasteurised before they go on sale. This means they are heated to a specific temperature for a specific time before being cooled down again. This inactivates enzymes and pathogenic bacteria, ensuring the product remains stable long enough to be distributed and sold in shops.

When this heat treatment is done with microwaves, it has several advantages. Among other things, the food can be packaged before it is heated up, as microwaves can penetrate plastic packaging. This makes it possible to pasteurise and sterilise the food significantly faster and with more even heat than traditional heating. The heat load on the food is much less, and thus more quality and nutritional content is retained. Microwave heating is therefore considered a gentle heat treatment method.

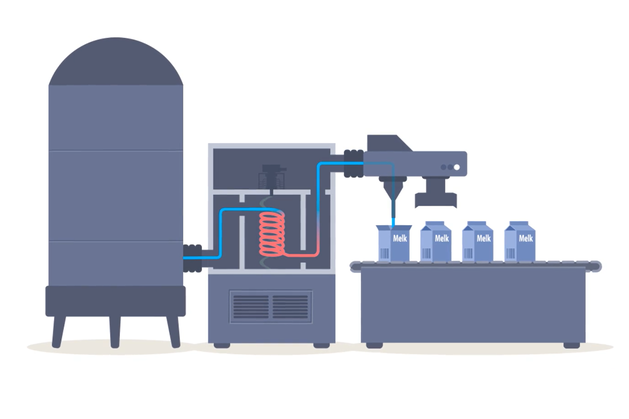

Pumpable foods and beverages

Foods that can be pumped, such as juice and milk, can be pasteurised by microwaves through a closed system. After heating, the drink is pumped through a cooler before being filled into pre-sterilised bottles or cartons in a sealed, sterilised chamber. The advantage is rapid heating without the drink needing to contact a much hotter surface, as in traditional systems. Such systems are usually delivered as complete lines.

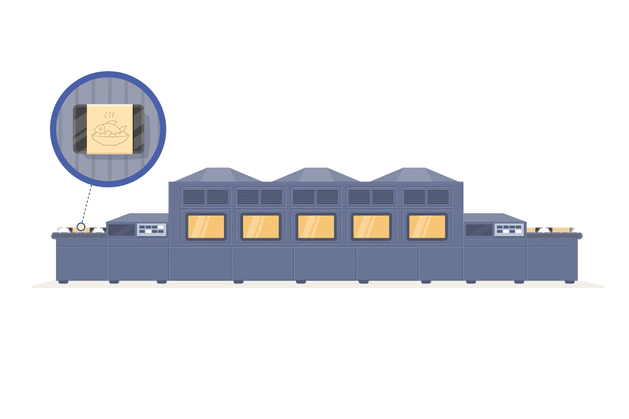

Packaged products

Complete production lines for pasteurisation or sterilisation of packaged products with microwaves are also available. Tunnels are the most common. Unlike autoclaves, which are traditionally used for heat treatment, tunnels can be used for continuous production. And there is much more freedom regarding packaging choice; for example, newly developed fibre-based trays can be used, as the outside is not exposed to water or steam.

But there are also challenges. One challenge is that pressure develops inside the packaging during heating. If the pressure becomes too high, the containers burst.

This is solved today in several different ways, for example by combining microwave treatment with overpressure and pressure locks that keep the bulging of the packaging in check. Another possibility is to use trays with valves or holes in the top film. It is also possible to control the power to avoid too high internal pressure in the packaging.

Learn more: Packaging when using microwaves

Drying in microwave tunnels

It is faster to dry food by microwaves than with traditional drying. The microwaves heat only the water that needs to evaporate from the product, so that the heat affects the product as little as possible.

As long as there is water left in the product, the temperature will not rise above the boiling point of 100°C. Microwave drying can therefore be very energy efficient and gentle.

However, foods that need to reach a very low water content can still become overheated, and even catch fire if too much power is used. The final part of the drying should therefore be done with air drying.

If it is important for product quality not to reach too high a temperature, the boiling point can be lowered with a vacuum. The microwaves then work in the same way as previously mentioned, but at a lower temperature.

Thawing frozen foods

Thawing and tempering are what the food industry most often uses microwaves for. A typical example is fish blocks at -30°C that need to be processed. The microwaves are used to quickly increase the temperature in the fish blocks to between -10 and -5°C. This is sufficient for the block to be cut or broken up for further thawing and processing.

Pre-treatment with microwaves

Microwaves affect chemical bonds. As explained for pasteurisation, the effect is not strong enough to inactivate bacteria, but for products that need to be dissolved or transformed through hydrolysis, for example, the microwaves can significantly reduce the treatment time.

How safe is it to eat food heated by microwaves?

Using a microwave oven is harmless. When the oven is turned off, the microwave fields are also completely turned off. They contribute to heating the food, and nothing else.

When the microwave oven came to the home market, radiation danger, or the risk of microwave energy leakage, was much debated. However, a household oven emits far less power than a mobile phone, and they use the same frequency.

There have also been questions about whether foods contain radiation after microwave heating. They do not. Microwaves are non-ionising, so nothing remains in the food.

What is worth considering, however, is that using full power for too long can lead to the food being burnt — and burnt food should be avoided.

Learn more: The effects of microwaves on food safety and shelf life

How sustainable is it to use microwaves in food production?

The most important environmental benefit of using microwaves for pasteurisation and sterilisation is that only the food is heated by the microwaves. One does not need to heat up equipment, process water, steam or other heat transfer media to heat the product.

- With traditional autoclaving, as much as 40% of the heat can go to heating equipment and process water, but this will vary.

- Where microwaves have been used for drying, the energy savings have been in the range of 30 to 40% compared to air dryers.

The energy source for microwave equipment is electricity. This is different from machines that use steam (autoclaves, pasteurisers). The rapid heating also means that the equipment has short operating time in relation to production volume. The products and magnetrons in the microwave equipment must nevertheless be cooled down, and how well this heat is utilised affects energy efficiency.

Like other pasteurisation and sterilisation, the products can get very long shelf life, so that there is potentially little food waste compared to fresh produce. Sterilised products can be stored at room temperature without using energy for cooling during distribution and storage.

Not all types of packaging materials can be combined with microwaves. On the other hand, it is not necessary to use material that is water-resistant on the outside, so that the possibilities for finding more environmentally friendly materials than plastic are present.

Research on microwaves in food production

Nofima has long experience with research and development of microwave solutions for food production. Here are some projects that deal with microwaves among other things:

Selected scientific publications

Learn more!

If you want to know more about

- the physics behind microwave heating and how the equipment is built up

- what kind of packaging can be used for microwave treatment

- advice for market communication of microwave-treated food

- research on how microwave treatment affects various foods

you should check out innovativefoodprocessing.no.