OptiBoost

Importance of gentle drying technology for the quality of fishmeal and for the quality, health and welfare of farmed salmon in critical production phases

Fishmeal is an excellent feed ingredient, but how can it be producd with even higher quality for the health, quality and welfare of salmon?

Start

01. Sep 2025

End

30. Aug 2028

Funded by

Norwegian Seafood Research Fund - FHF

Cooperation

Skretting AS and Pelagia AS

Project Manager(s):

Other Participants:

Background

Salmon feed has been in continuous change, and it is uncertain whether today’s farmed feed is optimal for salmon farmed under increasingly demanding production conditions. Experience from feed manufacturers and research shows that increased protein-to-lipid ratio in feed improves production efficiency, slaughter yield and muscle thickness in different weight classes of farmed salmon. High protein levels often come from increased inclusion of fishmeal in the feed formulation.

Fishmeal has traditionally constituted a large proportion of the feed as a balanced source of proteins and essential amino acids that ensure good growth in salmon. In line with increasing aquaculture production, there will not be sufficient quantities of marine resources to cover the protein requirement from fishmeal alone. The fishmeal included in feed for salmon should therefore be of good quality.

Pelagic fish and other marine species contain water-soluble protein/nitrogen fractions in the form of nucleotides, free amino acids (mostly non-essential), as well as other nitrogen compounds such as methylamines (TMAO) which are crucial for protecting marine fish against stress factors (salinity, low temperature in winter, water pressure etc.) in the ocean.

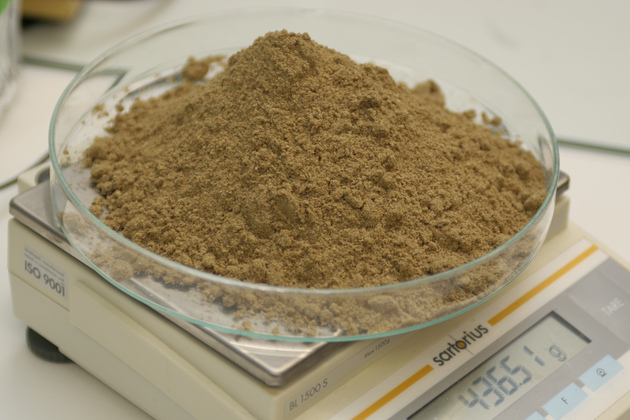

Commercial production of fishmeal is based on the production of a meal where the water-soluble components (the glue water) that are separated during the cooking process are returned and dried together with the fishmeal. Gently produced fishmeal dried at low temperature (LT meal) will normally have higher quality and digestibility than a standard fishmeal, but costs more to produce. Therefore, it is important to document more values and cost of high-quality fishmeal through documentation of feed utilization, growth, health, quality and survival of salmon in the sea and can contribute to better welfare and reputation of Norwegian farmed salmon.

Objective

To document the added value (functional properties) of gently produced high-quality fishmeal from different raw materials (blue whiting and herring) in feed for farmed salmon in critical production phases.

This is what we do

This project will compare the effects of different processing and drying conditions on the quality and function of fishmeal based on

1) Quality and composition of fishmeal

2) Stability and composition of water-soluble components .

In addition, the project will map how different qualities of fishmeal affect:

3) Osmoregulation and other functional properties in salmon smolt during particularly demanding production periods, i.e. during early sea release and in the growth phase of salmon under low winter temperatures.

Contact

Research facilities

Aquafeed Technology Centre

Files and Links