Worth knowing about canned food

In a world with lots of food waste, canned food is an ingenious method that provides long shelf life without the use of preservatives.

In 2018, the newspaper Dagbladet announced that canned food would leave the shops, with a headline stating that cans are leaving shops and will never return.

There is a misconception that all canned food comes in a metal tin, and it’s also not correct that all cans will soon be gone. Unil and Coop’s message in the article is actually that their own canned brands are transitioning to square cardboard containers instead of round metal cans in order to improve transport efficiency and thereby reduce their carbon footprint.

Canned goods = metal tin? No!

Many people in Norway often associate canned food with metal tins, especially the large round tins. These large tins are mostly used for ready-made meals that include fish balls, lapskaus (lobscouse stew) and spaghetti in sauce.

However, technically speaking, canning is a type of processing technology, regardless of the type of container used. If you buy chopped tomatoes in cardboard cartons or in a metal tin, both of them have been hermetically sealed. Today, hermetically sealed food is available in many different types of containers: metal tins made from steel (ready-made meals, vegetables) or aluminium (mackerel in tomato sauce, sardines, liver pâté, tuna), cartons (sterilisable cardboard cartons), pouches (sauerkraut), stand-up pouches (sauces and soups), plastic cups (ready-made meals, sandwich fillings), glass (pasta sauce, baby food) and soft aluminium (mackerel in tomato sauce, cat food).

The one thing that all hermetically sealed food has in common is the processing technology. The food is put into suitable containers and then hermetically sealed. In some cases, the food is raw when the container is sealed, but it may also be partially cooked. Hermetically sealed containers must be airtight and sealed against microorganisms.

After sealing, the food is cooked in a pressure cooker (autoclave) at a temperature of 110 to 135 °C over a period of time to achieve what is called commercially sterile products. The purpose of heat treatment is to kill all vegetative bacteria as well as spores of pathogenic bacteria that may be present in the food, including Clostridium botulinum, which has spores that are heat-resistant.

The length of time and the temperature used is a science in itself. The most important parameters in this process are the heat conduction that takes place in the food, the geometry and size of the container, the container material and the heating medium used in the pressure cooker. In addition, the type and number of bacteria that may be present and grow in the product also have to be taken into consideration. When one of the parameters changes, new processing requirements must also be developed. When properly carried out, enzymes are also deactivated and the shelf life at room temperature is greatly extended (for 2 to 5 years). A level of food safety is achieved that surpasses all other methods of preservation.

New container types, new challenges

A transition from metal tins to cardboard-based packaging (such as the Tetra Recart) would involve considerable investment and restructuring regarding production and processing. This would also mean having to acquire new filling and sealing systems and having to rebuild the autoclave trolleys to ensure uniform heat loads. Cardboard cartons also have a lower coefficient of surface conduction than metal, so the processing time is likely to be longer. In addition, containers that are square-shaped are at risk of being unevenly heated compared to round ones. This can cause burning at the corners and edges. Regardless of the container, the process must be designed so that the coldest point receives a sufficient heat load in order to make the food safe.

Although there are many alternatives out there, there is one thing that they can’t compete with against metal. Metal tins are 100% airtight and 100% lightproof, so when alternative containers provide 12 months of shelf life, the metal tin provides several years. Some sardine-lovers argue that the product becomes even better after a few years of maturing in the tin. In addition, the metal tin is 100% recyclable, just like glass.

Nicolas Appert – The father of canning

In 1809, Nicolas Appert won a competition in France to find the best way to preserve food for long periods of time. The competition was announced as a result of Napoleon’s wish for a better supply of food to his military troops, which he was planning to send deep into Russian territory. Appert’s solution was to boil the food in thick glass bottles that were sealed with wax immediately after boiling. This allowed the food to last for several weeks.

The following year, the tin can – made of iron, coated with tin to prevent rusting and sealed with lead solder – was launched and the first canning factory was established in London in 1813. This was more than 50 years before Louis Pasteur showed the connection between killing bacteria and heat. Everyone knew that canning worked, but not why. Eventually, it was also understood why pasteurisation didn’t preserve things forever, because spore forming bacteria need to be exposed to temperatures higher than the boiling point of water in order to be deactivated. As a result of this, counter-pressure autoclaves were developed, making it possible to raise the boiling point of the water enough to sterilize its contents. Along with the invention of the seam folding machine at the end of the 1800s, this laid the foundation for the industrialisation of canning and its heyday during the first half of the 1900s.

Canned food is here to stay

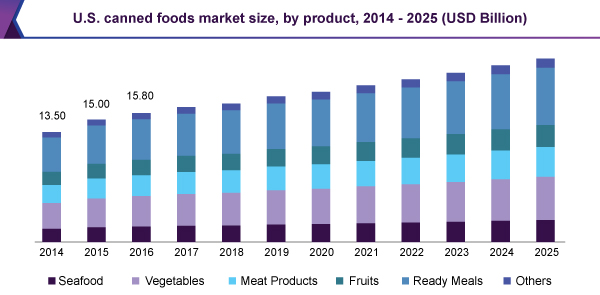

In a world with lots of food waste, canned food is an ingenious method that provides long shelf life without the use of preservatives. When food is cooked in a tin, the boiling water doesn’t take anything out from the food. Most of the vitamins, polyunsaturated fatty acids, minerals and overall nutritional value are retained, even though some water-soluble vitamins like vitamin C are somewhat degraded. Canned food has saved many people’s lives in disaster areas and the metal tin also keeps pests out. It is always a good idea to have a small food store that can be used if there is a power cut for few days, or as a backup option at your cabin. Apparently, many people agree, as the annual market growth for canned food has been 3.8% globally

Since Nofima was established in 1931 as a canning industry laboratory under the name of “Hermetikkindustriens Laboratorium”, we have been working to find ways to preserve food and help the Norwegian industry to find the best solutions for various needs. We have worked extensively on developing new variations of containers for sterilized products, and how to preserve the colour, taste and texture of the products with milder heat treatments. Here we use methods such as shaking, ultrasound and microwaves to reduce the process time. The heat treatment becomes even gentler when we combine it with high pressure treatment, resulting in the same level of food safety combined with long durability.

It is possible that we are slightly conservative, but we would argue that canned food will be present even in the stores of the future – along with pasteurized and chilled ready-made dishes and fresh products with a shorter shelf life.

Topics

Packaging materials