Molecular weight is a key to control quality

Consistent quality is the key to good products. By estimating the molecular weight and hence the size of the proteins, Nofima scientists can characterize and control the protein quality.

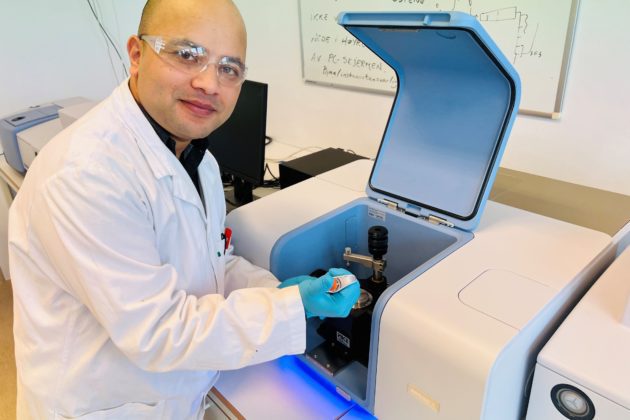

Quality control is an essential part of all types of production – and a field that really interests Bijay Kafle in Nofima. Now he is looking into quality of milk and by-products made from residual raw materials from poultry and fish.

He started studying quality control of pharmaceuticals and clinical pharmacy in his home country Nepal, then shifted to traditional medicine. Now, as a Ph.D. student in DigiFoods, he works with food and residual raw materials from the food industry.

A future in spectroscopic techniques

With a focus on FTIR spectroscopy, he has started to develop applications using a robust, cost-effective, and simple FTIR (Fourier Transform Infrared) instrument. The plan is to take FTIR spectroscopy closer to in-line by testing at process lines in the food industry.

– Previously, I have used different spectroscopy techniques and other technical instruments. My aim for the future is to work more on quality control of different foods and medicines using different spectroscopic techniques, says Bijay.

From pet food to human food

Norilia and Biomega, who are industrial partners in Digifoods , process residual raw materials from fish and poultry, respectively. They both produce value-added protein hydrolysates. . Currently, the main market for these by-products are animal feed and pet food.

However, a long-term goal is to increase the percentage of protein hydrolysates found in food and food supplements. Several of these food products are already currently being launched, but such a change also requires more consistent good quality. However, the industry does not characterize the protein hydrolysates, making it difficult to guarantee the quality of the protein hydrolysates.

Nofima researchers have found that average molecular weight is one of the parameters to monitor the enzymatic hydrolysis process and protein quality. Generally, the molecular weight can serve as a protein quality indicator, related to for instance taste, functional properties and composition.

– We are in the process of developing different applications related to prediction of molecular weights of protein hydrolysates using FTIR spectroscopy. Our aim is that an industrial FTIR approach both can be used to monitor the hydrolysis process and at the same time document product quality, says Nils Kristian Afseth, senior scientist at Nofima. He is also one of Bijays supervisors.

The steps of an industrial prototype

Bijay started his work by checking the quality of lab-based protein hydrolysates compared to hydrolysate samples obtained from food processing industries.. Different sampling techniques, FTIR-

ATR (attenuated total reflectance) with water background subtraction and FTIR dry films approach were applied. The reason for choosing these methods was to reduce the effect of water interference on protein spectra. Different preprocessing techniques have been applied and the FTIR spectra of protein hydrolysates are used to develop the prediction models for average molecular weight using multivariate regression analysis.

– It is necessary to adapt measurement methods and instruments to the condition of the sample. For example, water can interfere in FTIR spectra, and since protein hydrolysates contain water, it is more demanding to examine and control the quality of protein hydrolysates. Therefore, we have to adapt the FTIR approach so that it can be done in dried samples, Bijay explains.

In this process, the researchers mapped the protein quality based on the average molecular weight, against measured FTIR dry film spectra, allowing them to predict the protein quality. The dry film approach has potential for future use at-line in industrial settings.

Together with researchers from Sintef Digital, Bijay is in the process of developing a dry film FTIR prototype which will be compared with the established lab instruments, calibrated, and taken to industrial environments for industrial sample analysis.

– The prototype we are developing must be reasonable sized and robust enough when compared to the lab FT-IR so that we can bring it to industrial process lines. We must also make it as simple as possible to make and present the dry films to the instrument so that Bijay can gather enough good data during his industrial trials, explains Marion O’Farrell, senior scientist at SINTEF, and Bijays other supervisor.

Facts about FTIR spectroscopy

FTIR (Fourier Transform Infrared) is a spectroscopy technique that uses infrared light to initiate molecular vibrations in a sample. In just a matter of seconds, information can be gathered about the molecules that are present in the sample. The technique is frequently used in industrial laboratories for food analysis.

Research facilities