What causes the sunlight flavour in milk?

Most of us have tasted milk that has been left in the sun – it has a distinctive off-flavour. The reason is that milk and other dairy products turn rancid when exposed to light.

A glass of milk takes on a distinct sunlight flavour after a few minutes in the sun, as do butter and other dairy products. When strong, the off-flavour reminds one of singed hair. It is not only the sun that causes this off-flavour; any light can do so, and it can arise in dairy products that are exposed to light in, for example, shops. It is important for this reason to protect milk from light, in order to give it as long a shelf life as possible. Milk in Norway is sold in paperboard cartons that transmit little light, while in many other countries milk is sold in transparent plastic bottles, in which case the light-produced off-flavour becomes a problem.

A great deal of research has been carried out during the past 60 years in attempts to understand the cause of the off-flavour. It has long been assumed that vitamin B2 (riboflavin) in the milk initiates the process that leads to the off-flavour. Riboflavin is sensitive to light, and when it is exposed to light it will initiate the oxidation processes in milk that cause the off-flavour. However, riboflavin only initiates these reactions when it is exposed to violet and blue light: yellow or red light is not believed to cause any such negative effect. Surprisingly, at Nofima in Ås we have shown that orange and red light actually causes a stronger off-flavour in milk than blue light. And we have found out why.

Sensitive to light

Milk contains minute amounts of chlorophyll and its breakdown products. These substances end up in the milk since the cow eats green grass. Chlorophyll is extremely sensitive to light, and will also initiate oxidation in the milk. These newly discovered light-sensitive products are most sensitive to violet, orange and red light, and this is the cause of the strong off-flavour that arises when milk is exposed to red light.

So the question arises why this has not been discovered long ago in something that is so familiar and well-researched as milk. The answer is that the substances are present in milk in extremely low concentrations. Nobody has known about them. They were discovered by chance at Nofima some years ago, when we were using an extremely sensitive measurement method based on fluorescence. We have since then studied how light affects these substances in milk, and how this leads to the off-flavour. We have so far shown that the chlorophyll-based substances cause a much stronger off-flavour in milk than riboflavin. We have published several scientific articles on the subject, and these have been well-received.

Sensory panel

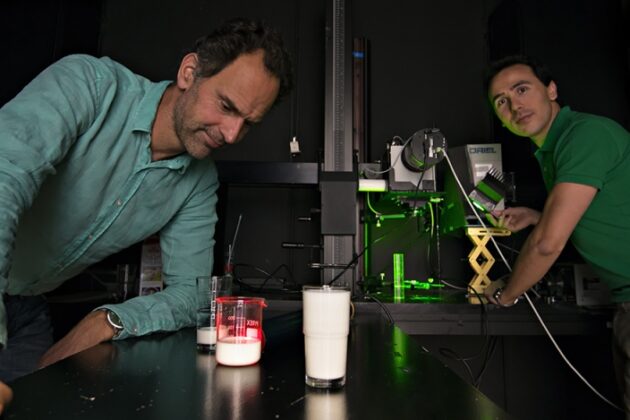

Another important factor that has enabled us to make progress in understanding the relationship between illumination and oxidation is that we have used the most sensitive instrument in the world to measure the off-flavour and smell of milk: A sensory panel. Such a panel consists of 10-12 people (most of them women) who can assess and quantify the taste and smell of food. The panel at Nofima consists of well-trained tasters, and has been accredited as an objective instrument. Advanced instruments are used within research to quantify smells, but we have found in all of our studies that the sensory panel is not only much more sensitive than these instruments, but also much more stable.

Knowing which substances in milk give rise to the off-flavour means that we also know how we can protect against it. The knowledge can be used to create specially designed packaging, and advice can be given about the type of illumination that should be used in shops to reduce the risk of an undertaste. This knowledge can be transferred to other foods, since there are several types of food whose quality is impaired when they are illuminated. We have our own laboratory at Nofima for illumination studies on food, not only to learn about the fundamental mechanisms, but also to be able to help industrial actors to discover the optimal storage conditions for their products.

The research has been financed by the Foundation for Research Levy on Agricultural Products (FFL) and the Research Council of Norway.

Publication

Contact person

Research areas

Quality and measurement methods

Raw material knowledge

Sensory sciences

Shelf life and food safety

Topics

Drink